Husky 1050 Air-Operated Diaphragm Pumps

1 inch Positive Displacement Double Diaphragm Pump

The Husky 1050 has a 1 inch (25.4 mm) connection and is available in aluminum, polypropylene, conductive polypropylene, PVDF, stainless steel and hastelloy.

The Husky 1050 air-operated diaphragm pump features a stall-free low pulsation air valve which provides a smooth and rapid changeover.

The one-piece center section eliminates leaks and reduces maintenance on Husky pumps when compared to other diaphragm pumps.

- Description

- Features

- Specifications

Description

Benefits of the Husky 1050 Double Diaphragm Pump

- Up to 5 times longer diaphragm life compared to other air-operated diaphragm pumps in its class

- Expanded material offering to handle endless applications

- Spring loaded, externally serviceable pilot valves for faster change over and reduced pulsation.

- Offered in ATEX configuration.

| Overview | |

| Maximum fluid flow | |

| Maximum Fluid Discharge Pressure |

125 psi (8.6 bar, 0.86 MPa)

|

| Maximum size pumpable solids | |

| Fluid displacement per cycle | |

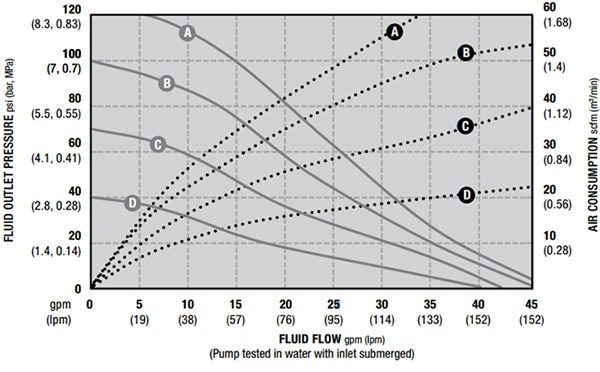

Husky 1050 Performance

Looking for a repair kit? Use our pump configuration tools to select the repair kit for your pump:

- Step 1 – Go to our Pump Selector Tool

- Step 2 – Fill in your pumps part number in the right corner

- Step 3 – Get an overview of all repair kits and accessories for your pump.

- 30% more efficient than the market leader

- 20% increase in fluid flow compared to the Husky 1040

- Up to 5 times longer diaphragm life compared to other double diaphragm pumps in its class

- Expanded material offering to handle endless applications

Husky 1050 Air-Operated Diaphragm Pump |

|

| Maximum fluid working pressure |

125 psi

|

| Air pressure operating range |

20-125 psi

|

| Fluid displacement per cycle |

0.17 gal

|

| Air consumption |

25 scfm at 70 psi, 20 gpm

|

Maximum values with water as media under submerged inlet conditions at ambient temperature: |

|

| Maximum air consumption |

67 scfm

|

| Maximum free-flow delivery |

50 gpm

|

| Maximum pump speed |

280 cpm

|

| Maximum suction lift (varies widely based on ball/seat selection and wear, operating speed, material properties, and other variables) |

16 ft dry, 29 ft wet

|

| Maximum size pumpable solids |

1/8 in

|

| Recommended cycle rate for continuous use |

93 – 140 cpm

|

| Recommended cycle rate for circulation systems |

20 cpm

|

Sound Power* |

|

| at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm |

78 dBa

|

| at 100 psi (7.0 bar, 0.7 MPa) and full flow |

90 dBa

|

Sound Pressure** |

|

| at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm |

84 dBa

|

| at 100 psi (7.0 bar, 0.7 MPa) and full flow |

96 dBa

|

| Fluid temperature range |

See Manual

|

| Air inlet size |

1/2 npt(f)

|

Fluid inlet size |

|

| Aluminum (1050A), Hastelloy (1050H) or Stainless Steel (1050S) |

1 in npt(f) or 1 in bspt

|

| Conductive Poly (1050C), Polypropylene (1050P), or PVDF (1050F) |

1 in raised face ANSI/DIN flange

|

Fluid outlet size |

|

| Aluminum (1050A), Hastelloy (1050H) or Stainless Steel (1050S) |

1 in npt(f) or 1 in bspt

|

| Conductive Poly (1050C), Polypropylene (1050P), or PVDF (1050F) |

1 in raised face ANSI/DIN flange

|

Weight |

|

| Aluminum (1050A) |

23 lb

|

| Conductive Polypropylene (1050C) and Polypropylene (1050P) |

18 lb

|

| Hastelloy (1050H) |

41 lb

|

| PVDF (1050F) |

26 lb

|

| Stainless Steel (1050S) with conductive polypropylene center |

36.3 lb

|

| Stainless Steel (1050S) with polypropylene center |

37.3 lb

|

| Stainless Steel (1050S) with aluminum center |

41.4 lb

|

Wetted parts include material(s) chosen for seat, ball, and diaphragm options, plus the pump’s material of construction |

|

| 1050A |

Aluminum

|

| 1050H |

Hastelloy

|

| 1050C and 1050P |

Polypropylene

|

| 1050F |

PVDF

|

| 1050S |

Stainless Steel

|

Non-wetted external parts |

|

| Aluminum (1050A) |

aluminum, coated carbon steel

|

| Hastelloy (1050H) |

hastelloy, stainless steel, polypropylene or aluminum (if used in center section)

|

| Plastic (1050P, 1050C, and 1050F) |

stainless steel, polypropylene

|

| Stainless Steel (1050S) |

stainless steel, polypropylene or aluminum (if used in center section)

|

Reference Information |

|

| Maximum Storage Time (varies with conditions) |

2 years

|

| Maximum Lifetime (varies with operating conditions and maintenance) |

10 years

|

| Power Efficiency Factor (varies based on pump configuration, operating parameters, and material) |

1.61 gal air consumed/1 gal fluid pumped at 70 psi

|

| * Sound power measured per ISO-9614–2. ** Sound pressure was tested 3.28 ft (1 m) from equipment. All trademarks mentioned in this manual are the property of their respective owners. | |