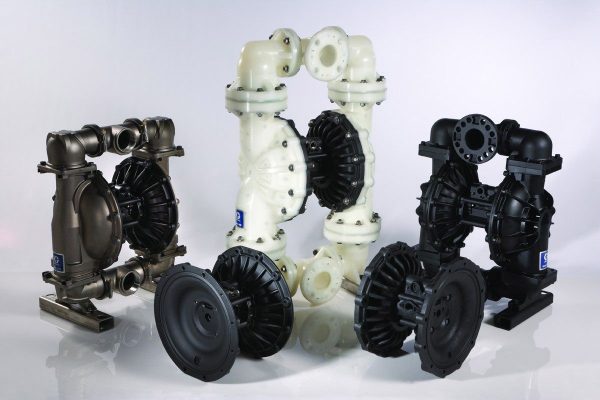

Husky 3300 Air-Operated Diaphragm Pumps

3 inch Positive Displacement Double Diaphragm Pump

The Husky 3300 has a 3 inch (76.2 mm) connection and is available in aluminum, polypropylene and stainless steel

The Husky 3300 air-operated diaphragm pump features a stall-free low pulsation air valve which provides a smooth and rapid changeover.

- Expanded material offering to handle numerous applications

- Flow rates up to 300 gpm (1,135 lpm)

- Modular stall-resistant air valve design

- Complete 3 inch family of diaphragm pumps available in aluminum or polypropylene center sections

- Heavy-duty construction

- Faster change over with spring loaded pilot valves

The one-piece center section eliminates leaks and reduces maintenance on the Husky pumps when compared to other diaphragm pumps.

- Description

- Specifications

Description

Benefits of the Husky 3300 double diaphragm pumps

- Overall improved efficiency (up to 40% more efficient)

- Highest fluid flow rate in its class

- Up to 5 times longer diaphragm life compared to other air operated diaphragm pumps

- Expanded material offering to handle endless applications

- Offered in ATEX configuration.

| Overview | |

| Maximum fluid flow | |

| Maximum Fluid Discharge Pressure |

100 psi (7 bars, 0.7 MPa)

|

| Maximum size pumpable solids | |

| Fluid displacement per cycle | |

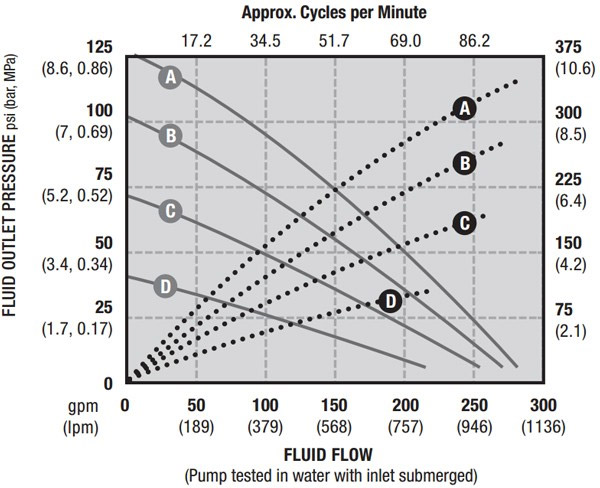

Husky 3300 Performance

Husky 3300 Air-Operated Diaphragm Pump |

|

| Maximum fluid working pressure | |

| Aluminum or Stainless Steel with Aluminum Center Section |

125 psi

|

| Polypropylene or Stainless Steel with Polypropylene Center Section |

100 psi

|

| Air pressure operating range** | |

| Aluminum or Stainless Steel with Aluminum Center Section |

20-125 psi

|

| Polypropylene or Stainless Steel with Polypropylene Center Section |

20-100 psi

|

| Air consumption | |

| All pumps |

90 scfm at 70 psi, 100 gpm

|

| Maximum air consumption* | |

| Aluminum or Stainless Steel with Aluminum Center Section |

335 scfm

|

| Polypropylene or Stainless Steel with Polypropylene Center Section |

275 scfm

|

| Maximum free-flow delivery* | |

| Standard diaphragms |

300 gpm at 125 psi

|

| Standard diaphragms |

280 gpm at 100 psi

|

| Overmolded diaphragms |

270 gpm at 125 psi

|

| Overmolded diaphragms |

260 gpm at 100 psi

|

| Maximum Pump Speed* | |

| Standard diaphragms |

103 cpm at 125 psi

|

| Standard diaphragms |

97 cpm at 100 psi

|

| Overmolded diaphragms |

135 cpm at 125 psi

|

| Overmolded diaphragms |

130 cpm at 100 psi

|

| Maximum suction lift (varies widely based on ball/seat selection and wear, operating speed, material properties, and other variables)* | |

| Dry |

16 ft.

|

| Wet |

31 ft.

|

| Recommended cycle rate for continuous duty |

35 – 50 cpm

|

| Recommended cycle rate for circulation systems |

20 cpm

|

| Maximum size pumpable solids |

1/2 in.

|

| Fluid flow per cycle** | |

| Standard diaphragms |

2.9 gal

|

| Overmolded diaphragms |

2.0 gal

|

| Ambient Temperature | |

| Minimum ambient air temperature for operation and storage. NOTE: Exposure to extreme low temperatures may result in damage to plastic parts |

32° F

|

| Noise (dBa)*** | |

| Sound Power |

99.1 at 50 psi and 50 cpm, 106.1 at 125 psi and full flow

|

| Sound Pressure |

91.5 at 50 psi and 50 cpm 98.2 at 125 psi and full flow

|

| Inlet/Outlet Sizes | |

| Fluid inlet – Polypropylene |

3 in. ANSI/DIN flange

|

| Fluid inlet – Aluminum |

3 in.-8 npt or 3 in.-11 bspt with 3 in. ANSI/DIN flange

|

| Fluid inlet – Stainless Steel |

3 in.-8 npt or 3 in.-11 bspt

|

| Air Inlet – all pumps |

3/4 in. npt(f)

|

| Wetted parts | |

| All pumps |

Materials chosen for seat, ball, and diaphragm options, plus the pump’s material of construction – aluminum, polypropylene, or stainless steel. Aluminum pumps also have carbon-coated steel

|

| Non-wetted external parts | |

| Polypropylene |

stainless steel, polypropylene

|

| Aluminum |

aluminum, coated carbon steel

|

| Stainless Steel |

stainless steel, polypropylene or aluminum (as used in center section

|

| Weight | |

| Polypropylene |

200 lb

|

| Aluminum |

150 lb

|

| Stainless Steel |

255 lb

|

| Notes | |

| * Maximum values with water as media at ambient temperature. Water level is approximately 3 feet above pump | |

| ** Startup pressures and displacement per cycle may vary based on suction condition, discharge head, air pressure, and fluid type. | |

| *** Sound power measured per ISO-9614-2. Sound pressure was tested 3.28 ft (1 m) from equipment. | |

| Santoprene® is a registered trademark of the Monsanto Co. | |

| Loctite® is a registered trademark of the Loctite Corporation | |